Combat Build-Up. Enhance Flow. Extend Equipment Life.

The Problem: Moisture-Driven Build-Up and Corrosion

In industrial environments, materials like coal, sulphur, cement, and phosphates are stored and transferred through silos, hoppers, feeders, and rollers. The moisture content of these materials can fluctuate significantly due to environmental and process-related factors.

When moisture increases, fine particles become sticky and begin to adhere to internal surfaces—especially in older silos made of steel or concrete. This causes:

- Flow blockages and inconsistent discharge

- Increased downtime for cleaning and maintenance

- Accelerated corrosion and erosion of the structure

- Long-term structural degradation and risk of unplanned outages

The Solution: Duromar® EAC / EAC-LV Epoxy Lining System

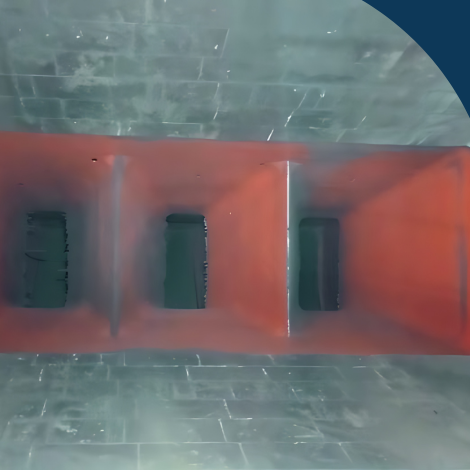

Arudra Engineers offers a proven lining solution using Duromar® EAC or EAC-LV—a high-performance epoxy coating applied at just 1mm thickness. It creates a smooth, non-stick, and corrosion-resistant surface ideal for the interiors of bunkers, silos, and hoppers. This coating prevents the sticking of bulk solids, resists acid attacks (especially from sulfuric acid due to moisture in sulfur or coal), and works effectively on both concrete and steel. By protecting against metal loss and structural decay, it enhances equipment lifespan, reduces maintenance frequency, and minimizes unplanned shutdowns.

HOW

IT WORKS ?

Duromar® HAR

Duromar® HAR is a trowelable bonding and protective putty designed to withstand high abrasion and impact. It performs exceptionally well in environments with fine coal dust, slurry, or ash particles, offering durable surface protection.

Duro-Tile sheets

Duro-Tile sheets, arranged in a hexagonal layout, are embedded into the HAR layer to form a tough ceramic barrier. This long-lasting surface prevents direct contact between abrasive materials and the underlying metal, extending equipment life.

Thermal and Captive Power Plants

Steel and Metallurgical Plants

Fertilizer and Chemical Industries

Cement and Mining Operations

The Duromar® lining system is ideally suited for industries with aging material handling infrastructure, providing long-lasting protection and reducing the need for frequent repairs. It is particularly effective for older silos and bunkers where ongoing patchwork is no longer viable or economical.

Duromar® EAC

Brushable epoxy coating with high chemical resistance

Withstands acids, alkalis, and abrasive conditions effectively

Suited for protective maintenance in harsh environments

Duromar® EAC-LV

Low-viscosity epoxy with excellent surface finish quality

Ideal where smooth flow and strong impact resistance are needed

Can be applied easily using a brush or roller on-site

Why Arudra?

With decades of experience in asset protection and maintenance services for process industries, Arudra Engineers is equipped with the tools, training, and coatings expertise to revive older infrastructure and enhance the performance of critical handling systems.

Our customized lining services are backed by advanced robotic application methods and material compatibility checks, ensuring optimal thickness, finish, and performance for each project.

Get in Touch

Protect your silos, bunkers, hoppers, and feeders with a reliable, long-lasting solution.

Contact Arudra Engineers for technical consultation or a site-specific lining proposal.