Reliable Tube and Tank Floor Inspection

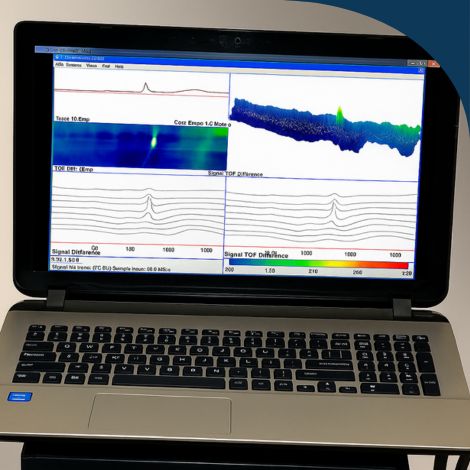

LFET is a non-destructive technique used to inspect boiler components such as superheater, water wall, re-heater, and economizer tubes in utility boilers. Performed from the outer diameter (OD), it detects both internal and external flaws, including corrosion, erosion, pitting, hydrogen damage, and caustic or phosphate gouging. Applicable to both magnetic and non-magnetic materials, LFET also supports tank floor scanning. Its ability to identify early-stage damage ensures improved reliability, extended equipment life, and optimized maintenance planning.

of Experience

Applications

LFET is used to inspect boiler tubes in power plants, including superheater, water wall, re-heater, and economizer tubes. It also applies to tank floor scanning and works on both magnetic and non-magnetic materials.