Advanced Tube Sheet Protection with Long-Term Corrosion and Erosion Resistance

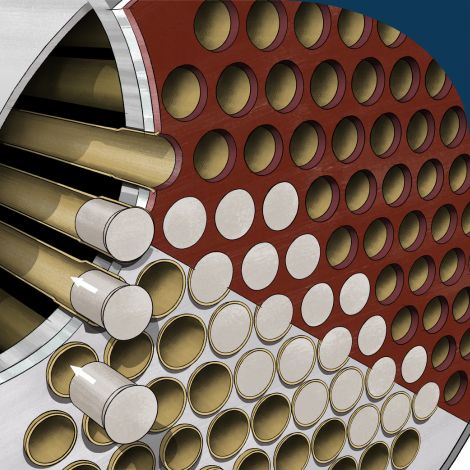

The plastocor® Cladding System is a specialized epoxy-based coating technology designed to prevent galvanic corrosion and mitigate erosion-related damage on tube sheets in heat exchangers and condensers. Developed by plastocor International SA (Switzerland) and exclusively applied in India and Asia by Arudra Engineers Pvt. Ltd., the system has set a global benchmark in extending the operational life of heat exchangers.

Widely adopted in power generation, petrochemical, fertilizer, and desalination industries, this system helps protect one of the most vulnerable components in a heat exchanger — the tube sheet — from degradation and failure.

of Experience

The Need for Tube Sheet Protection

Tube sheets in heat exchangers are exposed to harsh conditions, making them prone to corrosion and erosion. Galvanic corrosion arises from the interaction between dissimilar metals, like steel sheets and copper alloy tubes. High-velocity water, turbulence, and particulates also cause hydraulic erosion over time.

Consequences of Inadequate Protection

If left unprotected, tube sheets can develop leaks, suffer from frequent maintenance, and experience reduced efficiency. This deterioration leads to increased downtime, poor heat transfer, and in severe cases, total failure of the heat exchanger—resulting in costly repairs and operational disruption.

plastocor® Cladding System: The Protective Barrier

The plastocor® Cladding System is engineered to act as a durable, non-conductive, and erosion-resistant barrier that completely isolates the tube sheet from corrosive and erosive agents.

100% solids epoxy coating with zero VOC emissions

Non-conductive polymeric barrier that breaks the galvanic cell

Abrasion and erosion resistant surface designed for high-flow conditions

Customizable color and thickness to meet operational specifications

Application thickness typically 3 to 5 mm

Surface

Preparation

grit blasted to a white metal finish to ensure optimal

adhesion of the coating system.

Rebuilding Damaged Areas

Cladding Application

Curing and Quality Checks

Application Process

Our application process includes grit blasting to white metal finish, rebuilding damaged areas with plastocor® compounds, and applying a uniform cladding using airless spray systems. Final curing and quality checks ensure long-lasting protection and performance.

Advantages of plastocor® Cladding System

Arudra’s Expertise in plastocor® Applications

As an approved applicator of plastocor® systems since 2003, Arudra Engineers Pvt. Ltd. has successfully delivered turnkey protective solutions for heat exchangers across power, petrochemical, and industrial sectors in India and Asia.

Our teams are trained and certified by plastocor International SA and operate using:

- State-of-the-art surface preparation and coating equipment

- Oil-free compressed air systems and dehumidifiers

- Airless and plural component spray machines

Industry We Serve

Thermal and nuclear power plants

Steel and heavy manufacturing sectors

Petrochemical and refinery operations

Fertilizer and chemical processing industries

Desalination and water treatment facilities

Explore Additional plastocor® Solutions

Arudra also offers other high-performance plastocor® systems such as:

plastocor® Tube-Inlet System

Protects tube inlets against erosion and extends service life

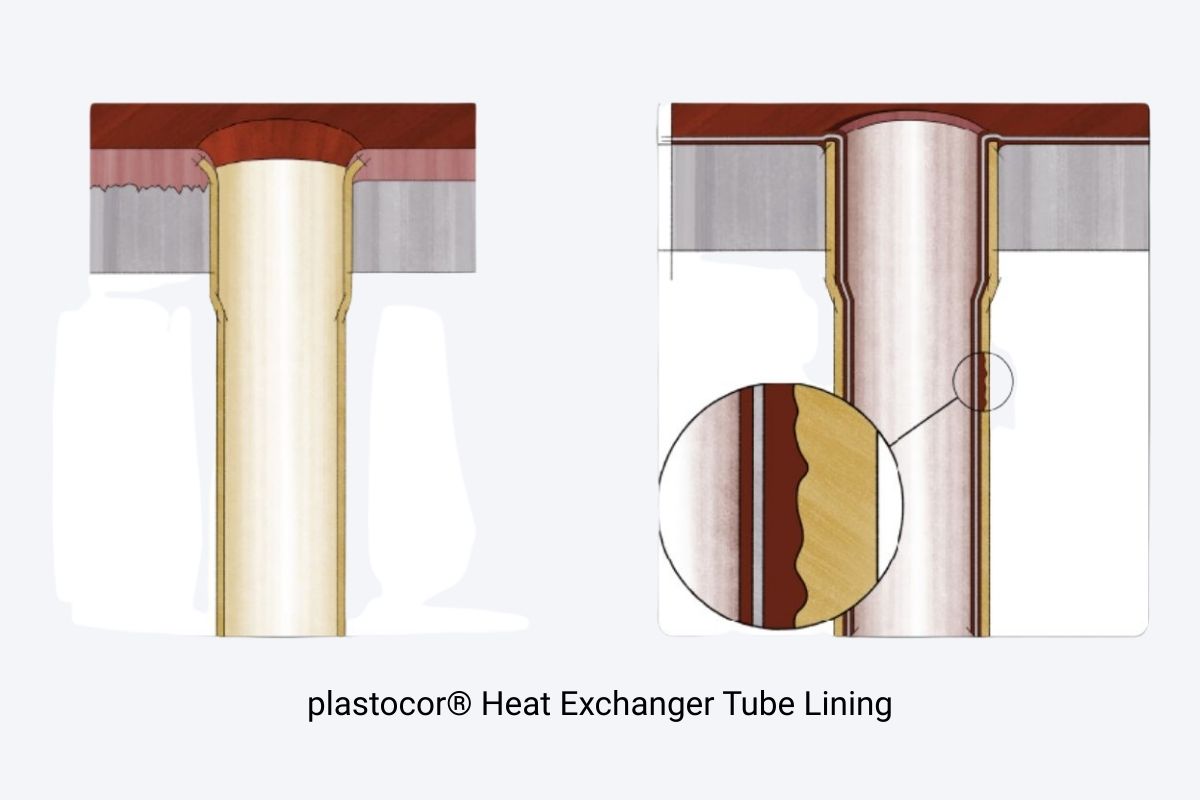

plastocor® Tube-Lining System

Provides internal tube protection for condensers and heat exchangers

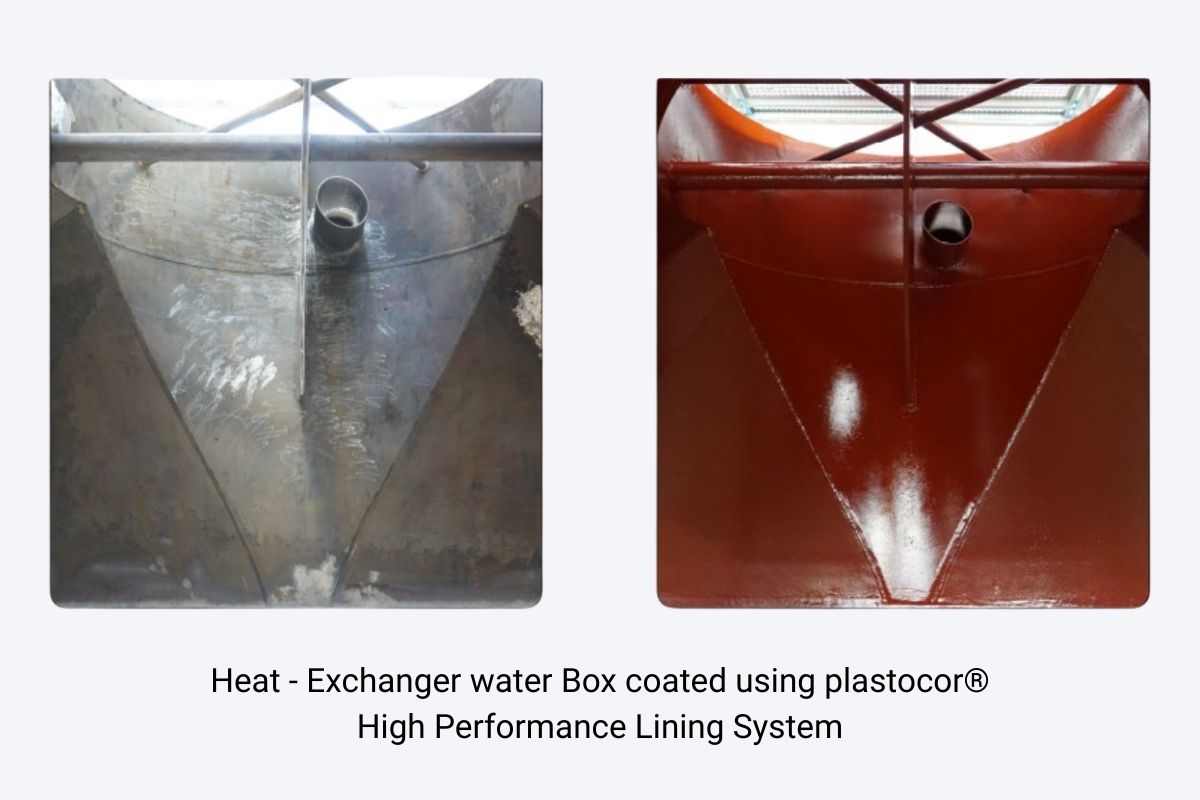

plastocor® High-Performance Coating

Shields waterboxes, chambers, and internal surfaces from corrosion

Connect with Us

To learn how the plastocor® Cladding System can extend the life of your heat exchanger assets, or to request a technical evaluation and site survey, please contact our engineering team via the contact form on our website.

For more information about plastocor® technologies, visit:

https://www.plastocor-international.com