High-Performance Coatings for Acid, Chemical, and Oil Storage Vessels

The Problem: Corrosion-Induced Tank & Vessel Failures

Corrosion is one of the leading causes of failure in industrial storage tanks and process vessels. Internal exposure to aggressive acids, alkalis, oils, and moisture can lead to:

- Severe metal loss and pitting corrosion

- Structural integrity failures

- Product contamination

- Increased maintenance and replacement costs

This is particularly critical for industries storing concentrated sulfuric acid, inorganic acids, and petroleum-based products, where conventional linings often fall short.

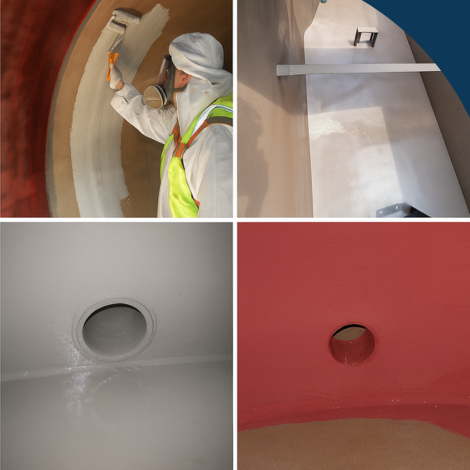

The Solution: Duromar® High-Performance Lining Systems

Duromar® offers a complete portfolio of epoxy and novolac-based linings that are engineered to withstand aggressive chemical environments—ensuring long-term protection and enhanced operational reliability for your critical assets.

1. Duromar® HPL-4310 & HPL-4320 XC

Acid Storage & Harsh Chemicals

Novolac, 100% solids formula

HPL-4310: Spray-applied resistance

HPL-4320 XC: High acid durability

Needs post-cure for best results

Ideal for tanks, sumps, ducts

Fast, even spray system use

2. Duromar® HPL-2310

Oil & Lubricant Tank Coating

Guards steel from corrosion

Moisture-blocking barrier layer

Low viscosity, long pot life

Brush, roller, or spray use

Resists oil and hydrocarbons

Fits diesel and lube tanks

3. Duromar® HPL-1110

External Tank Surface Protection

Epoxy for tank outer shells

Blocks UV, rain, and pollutants

Multiple color grade options

Smooth, durable, clean finish

Brush, roller, or spray ready

Prevents weather-based damage

Application & Equipment Compatibility

Arudra Engineers Pvt. Ltd. is equipped with generic singular spray and advanced cartridge systems to suit the specific mixing ratios and application methods required by each Duromar® product. Our experienced teams ensure:

01.

02.

03.

conditions

Extends tank life with durable, long-term coating, Protects assets in harsh operating conditions

Protect Your Tanks and Process Vessels with Confidence

Don’t leave your critical storage assets vulnerable to corrosion, erosion, and chemical attack. Choose Duromar® protective linings—backed by Arudra Engineers’ proven application expertise—for reliable and long-lasting performance.

Contact Us Today to explore product data sheets, arrange technical evaluations, or request a site-specific quotation.