Duromar® HPL-4323 – Flexible Epoxy Novolac Coating for Industrial Applications

Understanding the Problem: Dew Point Corrosion in Chimney Stacks and Flue Gas Ducts

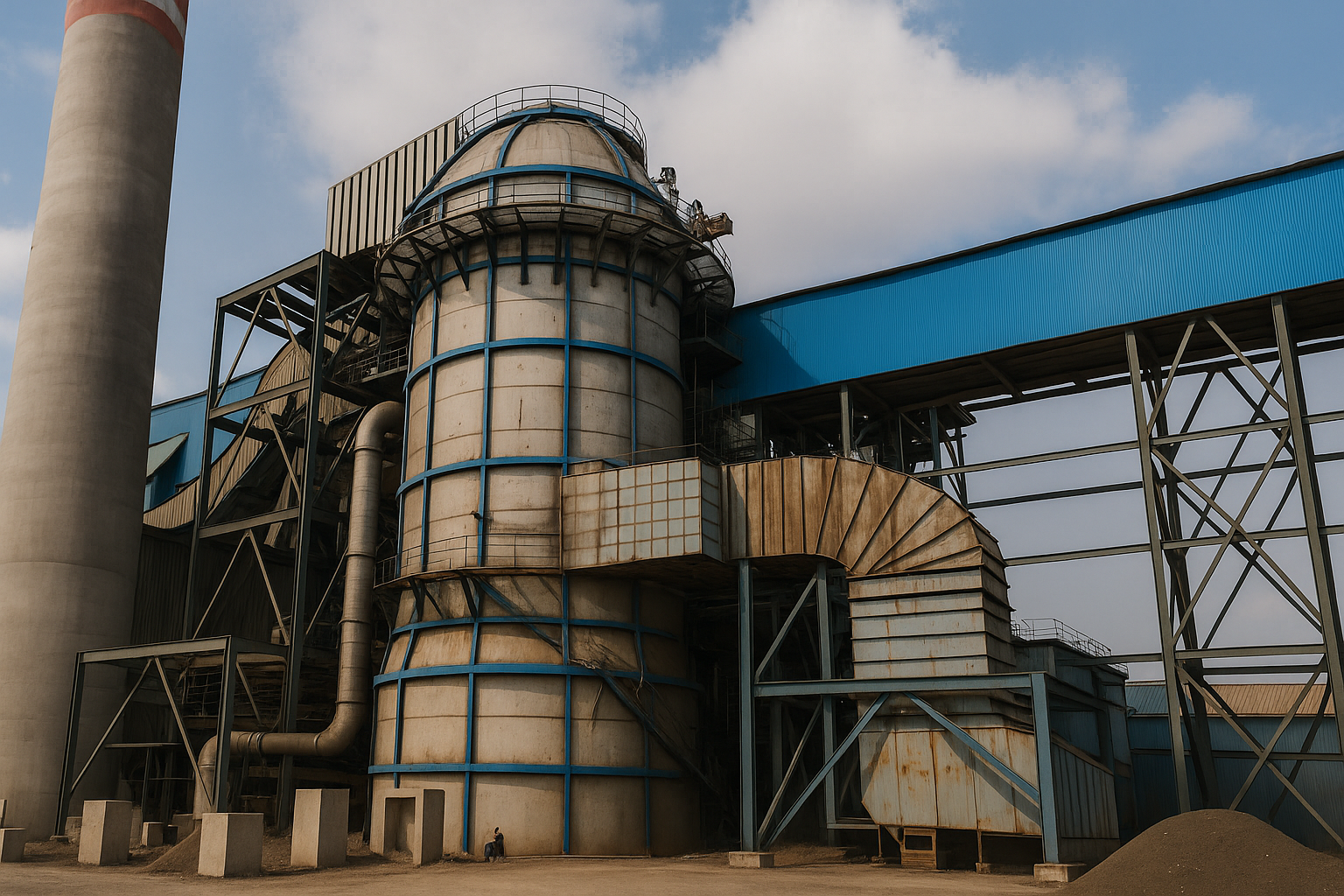

In many industrial processes, the combustion of fossil fuels generates flue gases containing harmful contaminants such as sulfur and chlorine compounds. As these gases cool, they can condense into corrosive acids like sulfuric acid, sulfurous acid, and hydrochloric acid. This occurs near the dew point temperature, where the air’s moisture condenses at a steady rate and pressure. This condition, known as Flue Gas Dew Point Corrosion, leads to significant damage in areas such as:

- Chimney stacks

- Flue gas ducts

- Convection sections

- Exhaust and emission pathways

Acidic condensation is a major threat to both carbon steel and stainless steel surfaces, particularly in environments with high humidity, fluctuating temperatures, or fuel-related impurities. When acidic vapors condense on internal surfaces, they initiate a highly corrosive reaction that can rapidly deteriorate metal integrity. If this issue goes unaddressed for even as little as two years, it can lead to significant wall thickness loss, pitting, and surface degradation. Over time, this compromises not only the structural integrity of the chimney or ducting system but also poses serious risks to operational safety and long-term plant reliability.

Fuel Contaminants

Prolonged Exposure

High Humidity Levels

Weak Coating Systems

Corrosion in chimney stacks is primarily driven by acidic condensation, often intensified by fuel impurities, high humidity, and inadequate protective coatings Over time, these factors lead to uniform corrosion, localized pitting, and structural degradation—posing serious risks to chimney integrity and operational

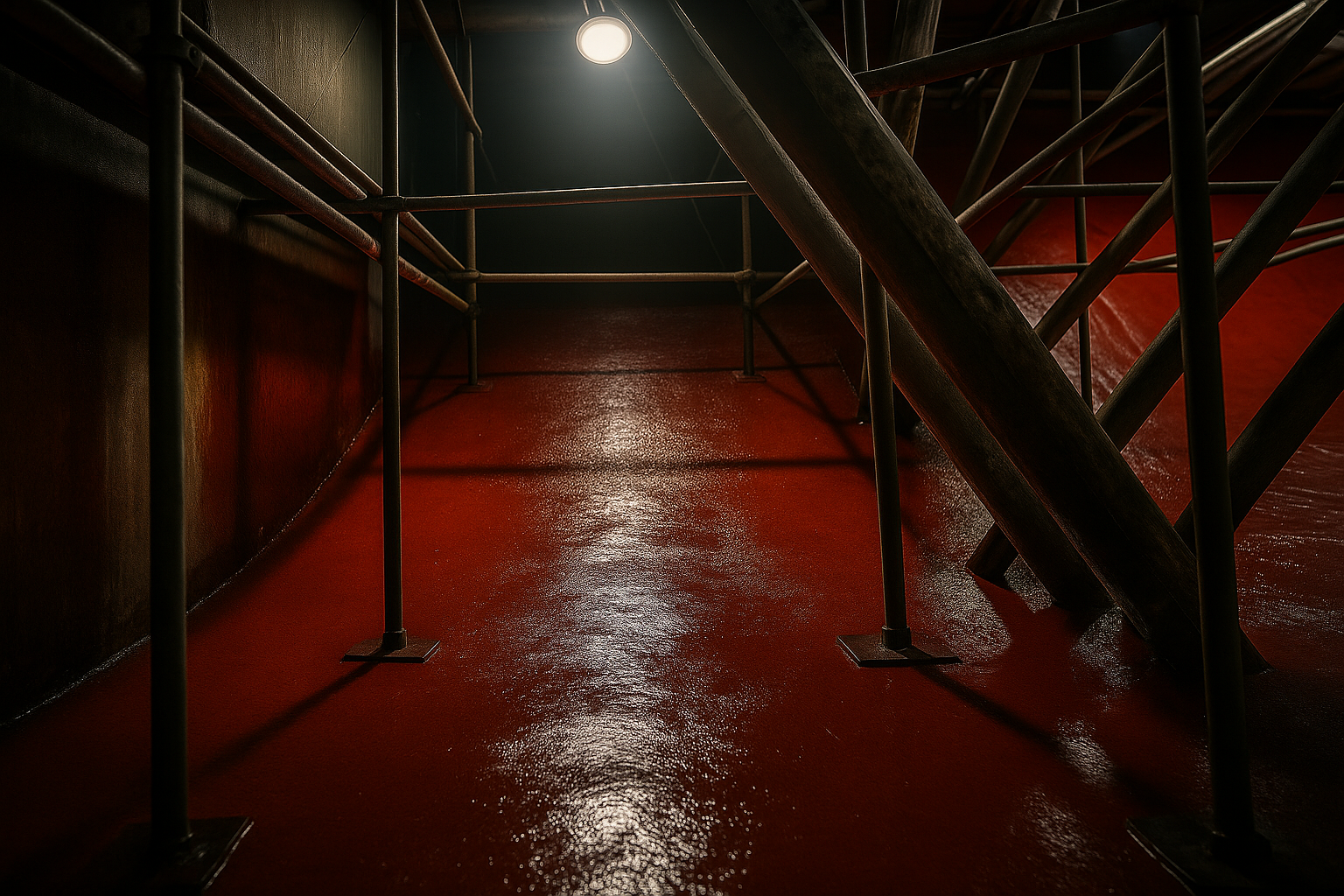

The Proven Solution: Duromar® HPL-4323 Epoxy Novolac Lining System

Duromar® HPL-4323 is a highly engineered, flexible epoxy novolac lining system designed specifically for use in chimney stacks, flue gas ducts, secondary containment structures, and corrosive environments. It provides long-term protection against acid attack, thermal shock, and abrasive wear.

Why Choose Arudra for FGD Coatings & Linings?

01.

Exceptional Chemical Resistance

02.

Flexible and Durable

03.

Superior Adhesion

04.

Rapid, Efficient Application

05.

Min. Thickness, Max. Protection

06.

Easy Repair and Maintenance

Product Technical

Profile

- Product Name: Duromar® HPL-4323

- Type: Multi-functional Epoxy Novolac Coating

- Hardener: Uniquely Modified Cycloaliphatic Amine

- Application Areas:

Designed for extreme chemical and thermal environments,Duromar® HPL-4323 is ideal for lining chimney and stack interiors, acid gas ducts, heat exchangers, and chemical containment vessels.It is widely used across refineries, power plants, and process industries where long-term protection against aggressive conditions is critical.

Enhance the Life of Your Chimney Stack

Duromar® HPL-4323 offers high resistance to dew point corrosion, extending asset life, reducing maintenance, and enhancing safety.

Key Benefits:

-

Longer equipment lifespan

-

Lower maintenance costs

-

Structural protection

-

Regulatory compliance

-

Quick application and turnaround

Ready to Protect Your Chimney from Dew Point Corrosion?

Duromar® HPL-4323 offers unmatched performance for flue gas and acid-resistant environments. If your facility is dealing with corrosion-related issues or if you’re planning preventive maintenance for chimneys and flue systems, we can help.

Contact us to discuss your requirements and receive a tailored solution for your application.